Milestones of The MassVentil Project: a race against COVID-19

15 July 2021

By the strategic cooperation with MEDICOR Zrt., the University of Óbuda and the inventors, the development of the MassVentil® mass ventilation system has entered a new phase.

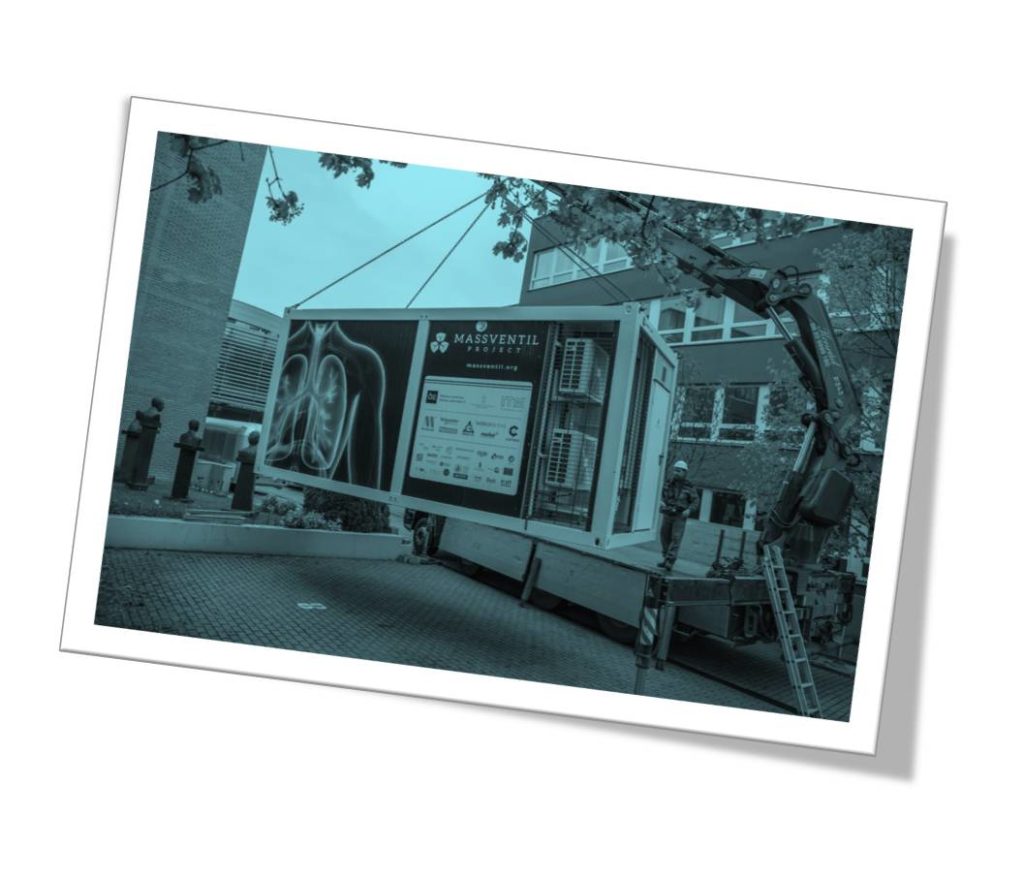

22 April 2021

The final prototype of the container was transported to the inner courtyard of the University of Óbuda. The construction of the container was supported by NKFIH and carried out by GANZ KK, thank you!

25 Feb 2021

While constructing the MassVentil container version, the task was to optimally arrange the elements of the equipment. And we also tested the safe transportability and the mobilizability.

26 Jan 2021

We have also created a mobile container that can be easily transported and used in a variety of emergencies, providing a quick and easy to move solution even in an environment without hospital infrastructure.

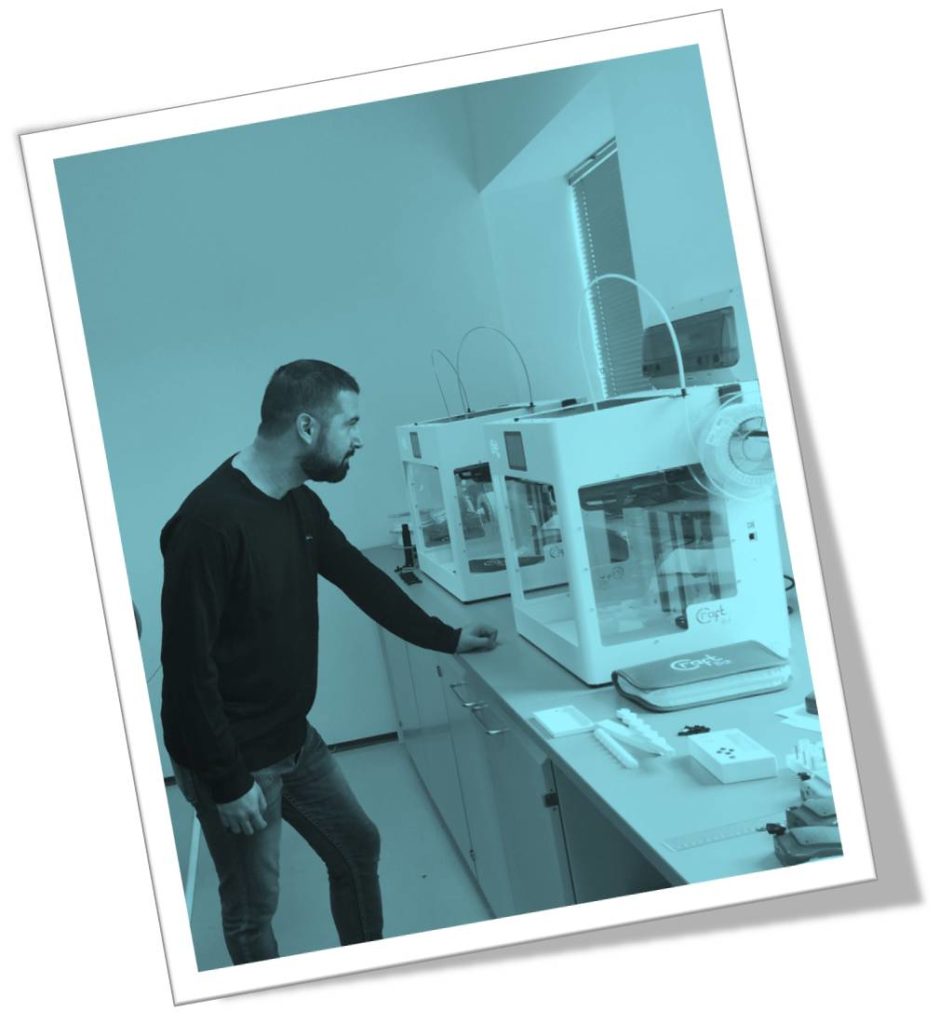

20 nov 2020

The new Craftbot 3D printers have been installed! The patient ventilator unit is designed in a way that multiple components can be manufactured by FDM 3D printers. Due to the complexity of the development, many elements have gained their ultimate form after several versions.

5 nov 2020

More and more people are interested in the MassVentil System from around the world, so in addition to the English-language materials, we have prepared Spanish-language brochure for those interested on the American continent. Click on the picture!

2 nov 2020

The picture shows the finished electric switch cabinet, which runs the engines of the MassVentil system.

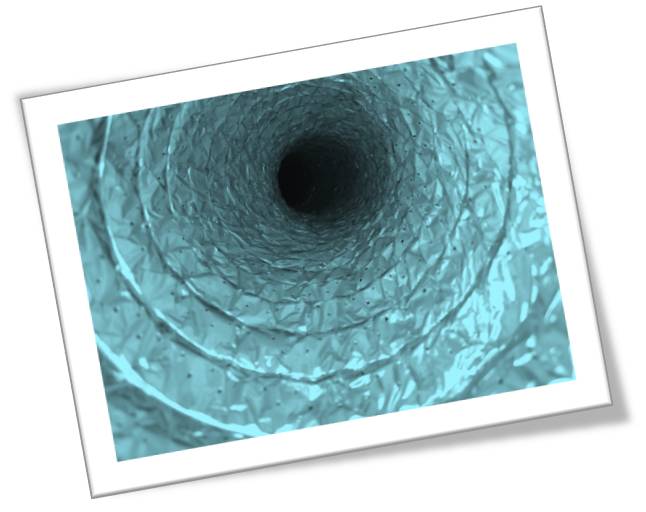

15 oct 2020

Behind the grid there are huge filters that clean the air flowing out, so that viruses exhaled by patients do not escape to the open hospital airspace. By this, we protect medical staff and the hospital environment.

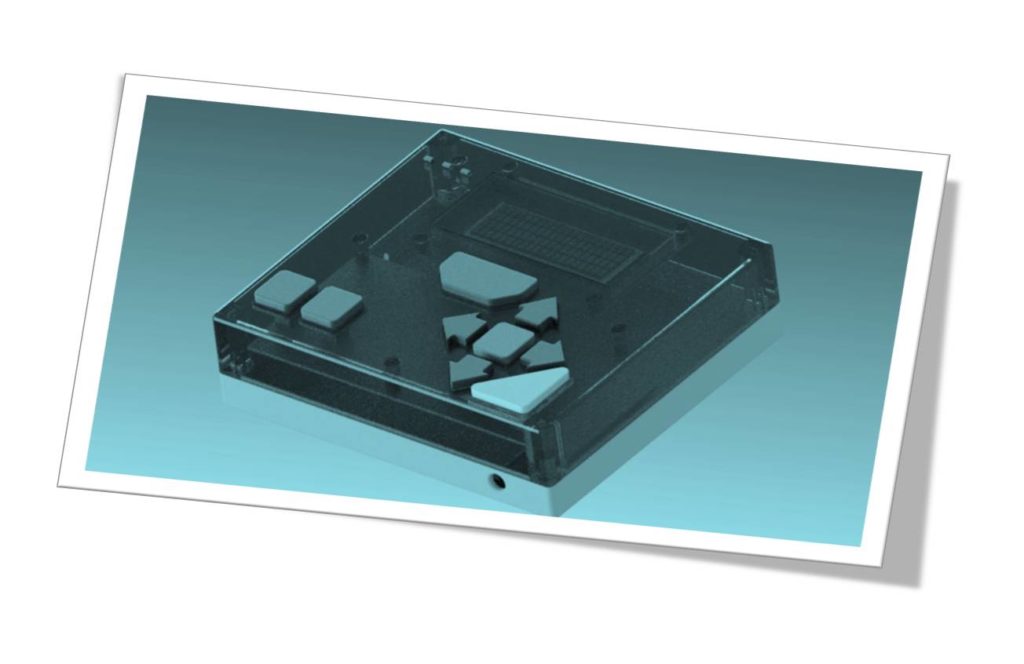

24 sep 2020

We have already designed the 4th generation of the personal ventilation unit and the 3rd of the central engine system. The pictures show the prototype of the latest version with a cover.

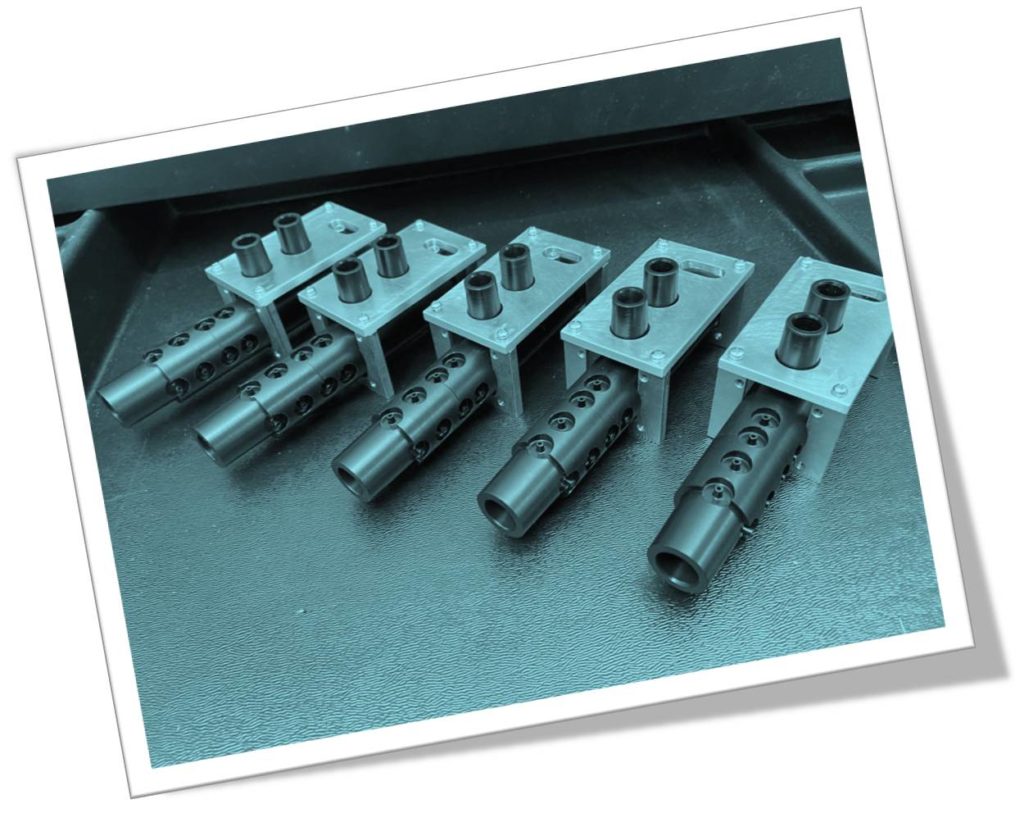

23 Aug 2020

The new generation valves (white) already have three inlets: inhaler, exhaler, extra oxygen.

25 July 2020

The frames of the new housings for the high-performance engines of the central duct system have been completed and assembled with the central motors, and the design of the sound-insulating cover of the engine housings has begun.

16 July 2020

A new dashboard version has been released that allows more efficient simultaneous monitoring of a larger number of patients.

2 July 2020

The buttons on the ventilator are redesigned to better support sterilization procedures.

17 June 2020

We are building a test system in a camp hospital. We analyse the user-friendly features of the system.

30 MAY 2020

We are ready with the essential elements. Already, five simulated patients might be ventilated simultaneously with the device.

19 MAY 2020

In addition to technical improvements, we have also begun to improve usability. The picture shows the prototype of the cover of the patient-side ventilator.

8 MAY 2020

We make newer and newer generations of valves, we can already add oxygen.

30 April 2020

MassVentil team took 1st place in the ventilator category in the pan-European hackathon, organized by the EU!

24 April 2020

We compiled the latest version of the MassVentil system specifically for testing purposes, which was also reviewed by László Palkovics, Minister of Innovation and Technology, State Secretary József Bódis and Minister of Finance Mihály Varga.

11 April 2020

We have finished some drawings about the valve of the Patient Ventilation Unit. We are starting to prepare a download area on the webpage to let visitors see what we are working on.

3 April 2020

We have successfully achieved patient ventilation for 3 simulated patients. All “patient” were ventilated individually. We have started drawing the CADs, and we are writing the code for the Dashboard of the MassVentil system, too.

26 March 2020

We launch formal communication of the MassVentil project to raise awareness. By this we expect to get more engineers and other professionals involved in order to advance faster, because the COVID-19 pandemic is spreading rapidly.

24 March 2020

Patient ventilation controls (even PEEP) are working well.

20 March 2020

An improved prototype is built, which has a real engine in the engine room and sensors are designed into the system.

16 March 2020

A handful of enthusiastic engineers assemble the first machine to validate the concept. At the time the motor used for ventilation is obtained from a home vacuum cleaner.

11 March 2020

The WHO declares the COVID-19 outbreak a pandemic. Countries are starting to buy ventilators, urging for supplies. There is hardly any equipment in developing countries.

2 March 2020

Dr. Miklós Kozlovszky, a research and development engineer, envisages a new ventilator that has three essential features: (1) no need for a dedicated machine for each patient, meaning that one ventilator can ventilate more than one patients at a time, (2) transporting exhaled infectious air from the common airspace, thereby significantly reducing the risk of infection for nursing staff; (3) the equipment may be installed on an ad-hoc basis in a non-hospital environment, without any hospital infrastructure.

February 2020

Italian experience shows that one of the biggest problems in saving lives is the lack of ventilators. Also, in the case of conventional ventilators, exhaled air flows into the common airspace, thus posing an increased risk to health personnel.

January 2020

COVID-19 appears in Europe, Italy declares a state of emergency.

December 2019

The COVID-19 epidemic is emerging in China and the whole world is following developments.